LCA

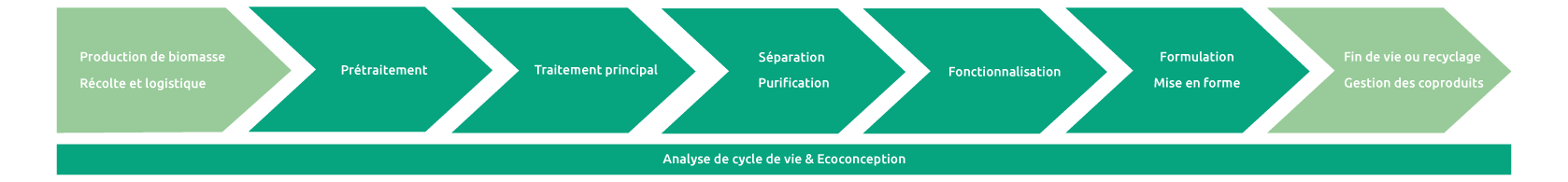

Green chemistry – Biomass fractionation – Biobased materials – LCA and ecoconception – Plant matter characterization

The Component presentation

The substitution of fossil carbon (petrochemicals) by renewable carbon (agro-resource chemistry) is a major research stake for the upcoming years through the development of bio-based products such as: bio-based materials, bio-lubricants, bio-solvents, surfactants and new chemical building blocks.

The LCA method is based on sustainable chemistry supported by the development of new transformation processes with a limitated impact on the environment and human health.

Areas of research

-

Biomass fractionation

-

Implementation of biopolymers - biobased materials

-

Chemical reactivity and biobased molecules conception

-

Environmental evaluation and ecoconception

Pilot equipments

Fractionation: extruders, "all fibers" extractor; filter presses, grinder; Chemistry: reactors (10-300L), thin film distillation columns; Bio-based materials: extruders, injection, molding machines, thermo-compression units, injection presses, continuous dryer...

Analytical platform

Liquid phase chromatography; Gas phase chromatography; Spectroscopy; Mechanical and thermal characterization; Image analysis; Physico-chemical analysis; Development of micro-sensors and micro-analytical laboratories; Sensory analysis and dynamic olfactometry

AGROMAT

The AGROMAT technology transfer platform is primarily dedicated to promoting the development of bio-based materials that are eco-friendly and processed using thermo-mechanical technologies derived from plastics engineering.

Success stories - Authentic Material

New materials obtained by uniaxial thermo-compression of waste containing scleroproteins.

Objective

To valorize agricultural and industrial waste containing scleroproteins (leather, wool, silk, horn, etc.) in the field of materials science

Background

Fibrous animal proteins represent a significant source of waste from certain sectors of the food industry (horn, wool) as well as the luxury industry (leather, silk). Their intrinsic natural properties—such as strength and durability—can be leveraged in materials applications.

Implemented approach

The approach consists of jointly developing pre-treatment processes (grinding) and shaping/forming techniques, along with the resulting materials. Two material families are proposed:

- 100% natural materials derived from a proprietary scleroprotein thermo-compression cooking process, and

- bio-based composite materials with a thermoplastic matrix.