LGC

Processes – Supply chain – Catalysis – Separation – Extraction

The Component presentation

The LGC’s objectives are to design, conduct, optimise and extrapolate new processes for transforming products, materials or objects.

The LGC closely links process, product and technology. The manufacture of complex, multi-constituent and multi-phase products with specific properties for use requires new approaches to the complexity and diversity of processes. These are being explored with a view to better integrating processes on multiple scales: from microreactors to pre-industrial units.

Its research, based on thermodynamics and physical, chemical, electrochemical and biochemical kinetics, is enriched by recent advances in numerical fluid mechanics, modelling and simulation methods and instrumentation.

Comptencies

-

Water and effluents

-

Energy

-

Materials production processes

-

Health engineering

-

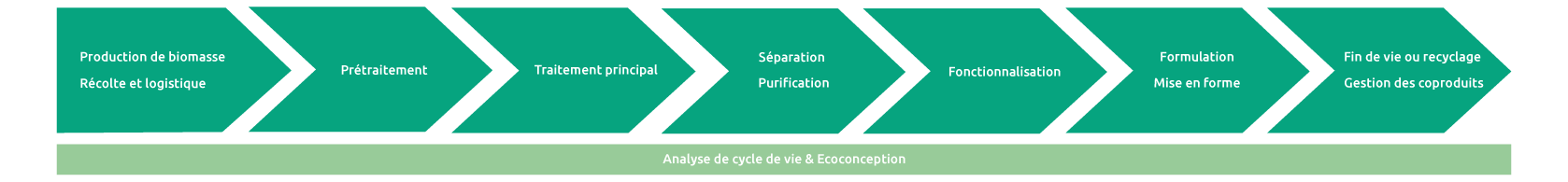

Bio-refinery

SAP - Analysis and Processes Services

The Analysis and Processes Department is a shared analytical department of LGC. This service brings together essential metrology for this laboratory with dedicated technical staff. The SAP's main mission is to carry out analyses for the LGC's research teams. However, the LGC also carries out numerous analytical services on behalf of companies or external laboratories.

CMA - Cell Measurement et Analysis

The Measurement and Analysis unit enables the development of new analytical methods and the installation of new equipment in compliance with safety standards. This unit enables the pooling, maintenance and renewal of analytical equipment on the Paul Sabatier University site.

ST LGC - Technical Service

The Technical Service (ST-LGC) is a shared service for the design, production and operation of experimental pilots and scientific instrumentation for the laboratory's researchers. Various trades are represented in the department, covering the full range of skills needed to build scientific instruments.

Success stories - Corrohm

A microbial fuel cell to protect reinforced concrete at sea

All reinforced concrete is subject to corrosion. Those exposed to a marine environment are even more so, as the salt in seawater accelerates the process. They are used, for example, in the construction of harbour quays, bridge piers or the bases on which offshore wind turbines are installed. To prevent this damage, one solution is to inject an electric current into the steel reinforcement of the concrete to stop or at least slow down the rate of corrosion. This process has a name: cathodic protection.

In Toulouse, scientists from the LMDC (Materials and Construction Durability Laboratory), the LGC (Chemical Engineering Laboratory) and the start-up CorrOhm have developed a process for producing this electric current in an environmentally friendly and renewable way, using micro-organisms found in marine sediments.