CRITT GPTE

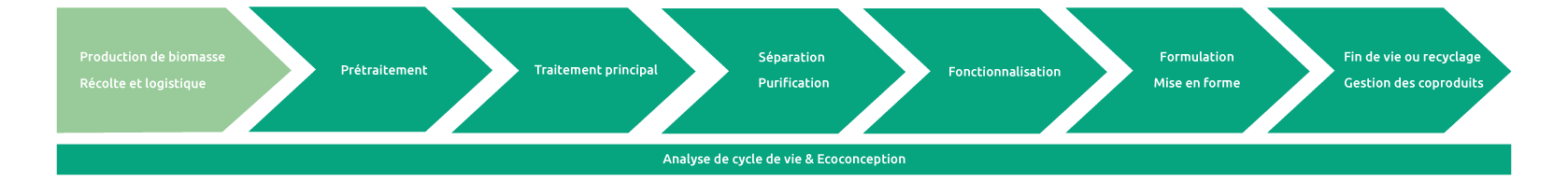

Production Processes – Environment – Sustainable Development – Bioprocesses – Chemistry

The Component presentation

For over 15 years, CRITT GPTE has been partnering with regional and national companies in the industrialization of production processes.

With its strong foundation in academic research and its technical capabilities, CRITT GPTE serves as a driving force for innovation, helping businesses stay ahead.

Our expertise in Process Engineering is reflected in our two main areas of focus:

- Industrial Process Engineering

- Bioprocess Engineering for the Environment

Areas of Focus

-

Chemistry and fine chemistry

-

Pharmaceutical and cosmetics

-

Agri-food and agro-industries

-

Treatment of Urban and industrial Effluents

-

Energy and sustainable development

-

Recycling of materials and products

Process Engineering

Unit Operations in Process Engineering: distillation, extraction, reaction, mixing, separation, crystallization, precipitation...; Liquid-liquid extraction technologies: counter-current columns, centrifugal extractors, mixer-decantor batteries...; Supercritical fluid processes: supercritical CO2 from laboratory scale (200 ml, 1000 bar) to semi-pilot scale (20 l, 690 bar); Process intensification; Custom pilot design.

Bioprocess Engineering for the Environment

Methanization Pilot: pilot reactors for anaerobic digestion (10 l to several m³), continuous online analysis of key operating parameters, additional offline analyses; Pilot for the treatment of industrial or urban effluents: experimental simulation of all unit operations; Custom pilot design.

Success stories - BIOTRADE

INFLEX: An Automated System for Optimizing Wastewater Treatment

INFLEX is a control procedure designed for the complete removal of nitrogen in single-basin systems, where nitrification and denitrification occur through alternating aerated and anoxic phases.

Unlike traditional management methods such as time tables, redox or oxygen & redox thresholds, INFLEX uses a dynamic analysis of dissolved oxygen and redox potential variations to pinpoint the key points marking the end of nitrification and denitrification. These variations are continuously monitored by an automated system that adjusts aerator operations and customizes the duration of aerated and non-aerated phases based on the incoming pollutant load.

Key objectives of INFLEX:

- Ensure process reliability

- Minimize energy consumption

- Simplify and streamline operator tasks

INFLEX has been successfully implemented at the wastewater treatment plants in Graulhet (38), Saint Céré (47), and Villefranche de Lauragais (31).